Exterior Timber Posts

One of the major decisions made was to remove the perimeter timbers posts and

use the Durisol walls as the load-bearing support for part of the

timber frame. Interior posts will stay (of course). N.E.W. and Chuck

will work together to design a timber plate attached with cast-in bolts

to pick up the floor joists. We will use an epoxy-set bolt system and

will either use decorative bolts or simply use flat black paint. We

will probably need a deeper housing than normal for the timber ledge in

order to drop the floor joists.

N.E.W. will install the plate as part of the raising.

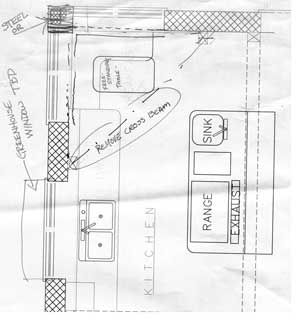

The corner cross beams are eliminated on the first floor in the kitchen and the stairway.

Interior Ceiling Material/Finish

We also determined that we would use drywall for the ceiling material so

the ceiling SIPS should have 5/8" spacers on the rafters.

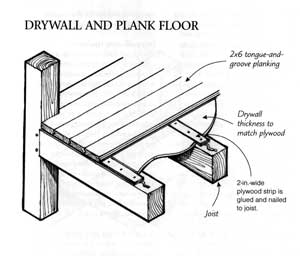

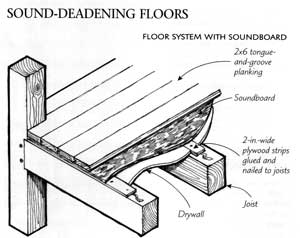

Second Story Flooring

The book Roger brought, The Timber-Frame Home, by Tedd Benson (Taunton

Press), had good examples of floor assemblies on pages 220 & 221:

|

|

Construction of the Tower

The first level of the breezeway will be part of the timber frame for an

impressive main entrance, but we will complete the rest of the bridge as

stick frame using plastic lumber for the exterior cantilevered part of

the second level and the floor of the third level (tower).

(LINK TO PDF

HERE) Elizabeth found several sites for structural Recycled Plastic

Lumber (RPL). There is a good article, which I have re-hosted on the

Web site as well.

Durisol Dimensions (in particular; thickness)

The blocks we are using are 12" X 12" X 24", with some instances where

half-blocks and corners are used. Detailed information from Durasol

is available here.

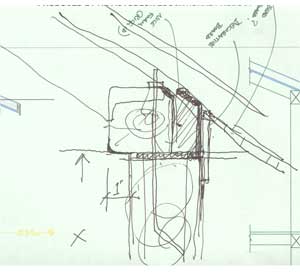

Windowed Corners

Construction on windowed corners on both levels on the NW side of the

house (North Corner and West Corner) will use steel poles to support the

corners rather than Durisol blocks to keep the view unobstructed

and make the corner less "heavy" in design.

See sketch above of kitchen corner.

Window bays in living room

Elizabeth will create some perspective renderings to determine the

fenestration of the NE side of the living room considering Chuck's

suggestion of keeping the East corner symmetrical.

Creation of Drawings

The discussions were complex regarding the detail required for the

joining of the SIPS, timbers, and Durisol at the roof line, the floor

joists and construction, and the coordination of the timber drawings

with the construction plans. Therefore it is critical that the

architect and the timber framers work closely in the creation of the

drawings for the next step. Given the close proximity and immediate

availability of New Design Works and New Energy Works, it makes sense

for Chuck to work with Mike to create the Foundation Plan,

Electrical Plan, and the interface between the durisol walls and the frame.

We can pass files back and forth quickly while

refining the details and making sure that we have everything in the

right place before printing out the final drawings.

Chuck's experience with Durisol and of course, working with N.E.W is also extremely useful.

There was a discussion on how exterior walls would meet and be finished. Here is the sketch from that conversation.

We will still need many drawings for the interior elevations and detail sections of the design that will be critical later on in the process and we will probably then use Tranquil Waters for that phase if I am unable to create those drawings myself.

Roof SIPs

There were several emails back and forth regarding SIPs for the ceiling construction.

Concernsw are cost, environmental impact (including shipping distance), energy efficiency and fire rating, and

structural strength. Mike is sending us an estimate using Winter Panel in Vermont. eurathane panels,

which are thinner than EPS with the same structural and R-rating of thicker EPS panels

from R-Control in Virginia.

ACTION ITEMS

(I didn't put dates on much of the action items because it is understood that

most of the items are to be done as soon as possible.)

N.E.W. - Mike Harvey